MicFil Ultrafine Filtering

and Fuel Optimization

-

Longer standing times

-

Improved lubrication and less wear

-

Improved combustion and less soot emissions (PM)

The advantages

For all engines, transmissions and hydraulic installations.

- Keeps engine-, transmission and hydraulic oil permanently clean

- Filters 98% more particles and water than a standard filter

- Filters up to 20 times more finely than standard filters, this leads to longer standing times of the oil

- Ensures better lubrication, the oil lasts longer, leads to less wear

- Lower maintenance- and repair costs

- Protects engine, transmissions and hydraulic installations and extends the life span

- Protects fuel injection systems by cleaner and anhydrous fuel

- Better combustion, lowers emission of particularly soot (PM)

- Prevents combustion residues and sludge

- Less harmful to the environment because of lower oil consumption

- Improved engine performance because of less attrition

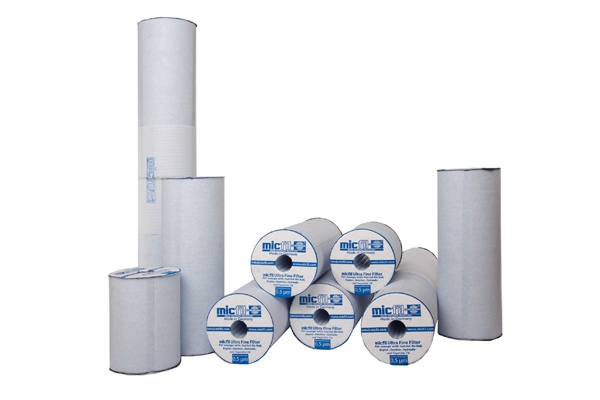

Product overview

Filter Housing

The MicFil ultrafine Filter housing is made of stainless steel or aluminum, and meets the requirements of the IACS, TUV, RINA, UMTEC and Bureau Veritas.

Filter element

Why DBH Diesel Engines?

24/7 service

We are accessible 24/7 so that we can help you worldwide, whenever you need us.

Knowledge and Experience

DBH works with trained and qualified engineers, to guarantee the highest quality.

Parts in stock

Essential parts can be supplied directly. All other parts are available in short term.

Clear communication

We agree on the proceedings to be carried out and inform about the progress daily. In this way you are always up-to-date.

Up to 90% of the defects in hydraulic systems are due to polluted oil

Maintenance of hydraulic oil is often neglected. Frequent maintenance is crucial for good functioning of the installations. In modern installations hydraulic components move over an oil film. This thin oil film guarantees a smooth operation of the installations. In practice a lot of press fluids are heavily polluted. The Mic Fil ultrafine filters provide a permanent cleaning of the oil and absorption of water.

It makes the components wear less quickly and reduces the risk of defects.

Clean and anhydrous fuel prevents faults of injectors and injection pumps

The high injection pressure in modern diesel engines requires a dry anhydrous fuel. In many cases standard filtering is not enough. By using MicFil ultrafine filters, the life span of injectors and injection pumps will be considerably expanded.

MicFil Fuel Optimizers expand the life span of the fuel injection systems

MicFil Fuel Optimizers feature high energetic magnetic fields. They ensure that the molecules are electrostatically charged during the flow of the diesel. This works against clotting of the fuel molecules and improves the combustion.

- Improved combustion

- Less soot and smoke formation

- Prevents combustion residues and sludge

Water separators

Fuel polluted with water can cause great damage to fuel systems. This certainly applies to the current high pressure common rail systems. The MicFil water separator will remove up to 99,2% of the water and solid particles to 10 micron from the fuel. Because of a combined use of a MicFil filter together with a water separator bacterial growth can also be prevented. This bacterial growth can occur through condensation in the tank with higher temperatures. The mucus formation caused by these bacteria can block the filter system and cause severe damage to the fuel system as well.

Operation

When fuel runs into the unit a whirl is caused by which the water and solid contamination are separated. The pollution will sink to the bottom of the separator, where it will be detained and can be drained. The pollution can be drained by hand as well as automatically. Optionally, a sensor can be added that gives a signal when the system is full.

- Prevents fuel/water related defects

- Removes solid/ semi-solid contamination particles, like dirt, rust and sludge

- Ensures that the emission standards are respected

- Longer MicFil and engine filter life span.

- Removes 99,2% of the water